- Lean is a philosophy or methodology

- Isn't something you do

- You "think" in a lean way.

- You use tools to embody

Lean Definition

Lean is a (1) systemic (2) pursuit of perfection with (3) relentless identification and (4) elimination of waste and (5) non-value added work.

There are five aspects of it as seen in the above statement.

- Systemic

- Pursuit of perfection

- Relentless Identification

- Elimination of waste

- Non-value-added work

- Sakichi Toyoda -- Toyota Motor Corporation

Flow

Achieve smooth flow as in a river

Rocks, leaves/ branches inhibit the flow

When the flow is smooth --- waste is minimal, and velocity is high VICE VERSA.

Three kinds of work

- Value-added (VA). All three must be met for a task to be value-added.

- This is something the customer is willing to pay $

- It is right the first time. Rework is a waste

- Transformational meaning changes form (physical characteristics of the product like shape, weight, colour, etc.) / fit (fits intended application) / function (Function of what the product actually does) -- the task must change the form fit or function of the product for it to be considered value-added. An exception though is an inspection at the assembly line - it is required so we don't let out a bad product.

- Value enabling work (VE)

- Is something that has potential for elimination in future but not immediately.

- Some but not all of change to form / fit or function.

- Example banks doing a credit check - would you be willing to pay for it. I won't be. But it also depends on who the customer is. An individual wouldn't pay, however if the customer is a bank, it would be willing to pay.

- VE is usually related to regulatory / compliance (SIRA for long tail claims).

- Non-value added work (NVA)

- This is waste

- Waiting - no changes to form, fit or function.

- Rework - not done fight first time

- Transportation - Movement of work between work stations.

- Movement - How do you work? work moves between me, manager, to someone else, back to me, goes in loops. All this is waste.

- Overproduction - too much of production

- Over-processing - do something even before it is needed.

- Inventory - excessive inventory, order only what you need

- Not utilizing staff to full potential - using a highly skilled person to do silly jobs.

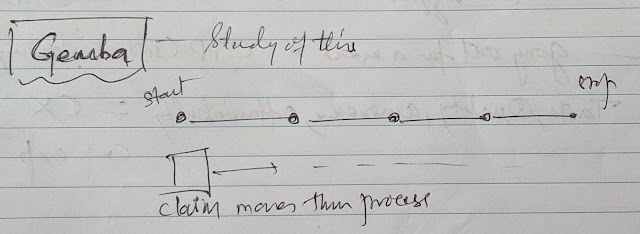

Gemba

Value stream

No comments:

Post a Comment